| Reference No. | 41492 |

| Year | 2001 |

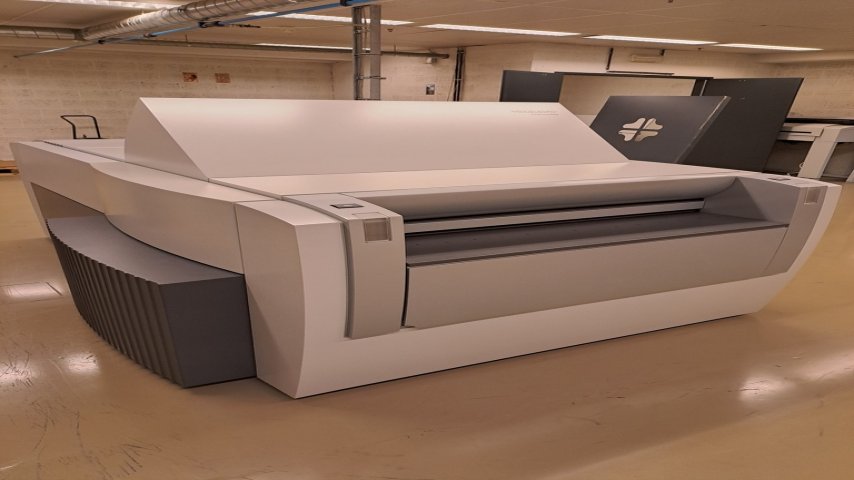

| Manufacturer | Heidelberg |

| Type | SM 52-2 |

| Main Category | Sheet Offset |

| Sub Category | 2 Colors |

| Size | 370 x 520 mm |

| Price | on request |

➕

More Details

Impressions : 63 Mio

Status : Stock

Location : Germany

Incoterm: FCA

Description:

The Heidelberg SM 52-2 is a versatile two-color straight printing press, manufactured in 2001 and currently in operation at a printshop in Germany. With a format of 370 x 520 mm and 63 million impressions, this machine is built for reliability and high-quality sheetfed offset production. The press features the Alcolor automatic film dampening system for consistent ink-water balance, and the Autoplate semi-automatic plate change system for efficient job transitions. Precision is ensured by the Cptronic control system and chromed cylinders, while integrated blanket and ink-roller wash-up devices simplify maintenance and reduce downtime. Additional features include a powder spray and cooling unit for optimal print conditions. The press supports a wide range of substrates, handling sheet sizes from 105 x 145 mm up to 370 x 520 mm, and paper thicknesses from 0.03 to 0.5 mm. With a maximum speed of 15,000 sheets per hour, it is well-suited for both commercial and specialized printing tasks. The machine comes complete with all manuals, tools, and accessories, ready for immediate integration into any print operation.

Impressions : 63 Mio

Status : Stock

Location : Germany

Incoterm: FCA

Description:

- Two colours Straight machine

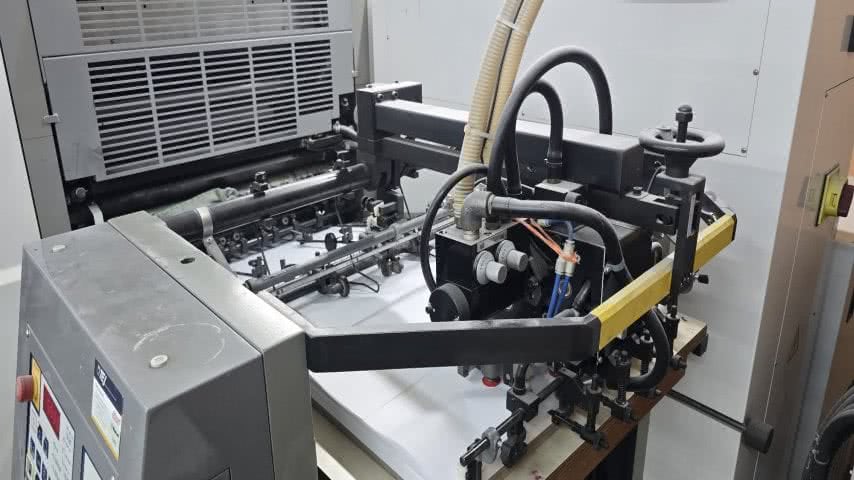

- Alcolor Automatic film dampening

- Autoplate: semi-automatic plate change system

- Cptronic , Chromed cylinders

- Blankets wash-up device - Wash device for impression

- Ink-rollers wash device managed from console

- Powder spray, Cooling unit

- All manuals, tools, accessories

- Technical details: Maximum sheet size: 370 x 520 mm - Minimum sheet size: 105 x 145 mm

- Paper thickness range: 0,03 - 0,5 mm - Max. speed: 15.000 sheets/hour

The Heidelberg SM 52-2 is a versatile two-color straight printing press, manufactured in 2001 and currently in operation at a printshop in Germany. With a format of 370 x 520 mm and 63 million impressions, this machine is built for reliability and high-quality sheetfed offset production. The press features the Alcolor automatic film dampening system for consistent ink-water balance, and the Autoplate semi-automatic plate change system for efficient job transitions. Precision is ensured by the Cptronic control system and chromed cylinders, while integrated blanket and ink-roller wash-up devices simplify maintenance and reduce downtime. Additional features include a powder spray and cooling unit for optimal print conditions. The press supports a wide range of substrates, handling sheet sizes from 105 x 145 mm up to 370 x 520 mm, and paper thicknesses from 0.03 to 0.5 mm. With a maximum speed of 15,000 sheets per hour, it is well-suited for both commercial and specialized printing tasks. The machine comes complete with all manuals, tools, and accessories, ready for immediate integration into any print operation.

_0_F004.jpg)