- Home

-

Machinery List

Machinery List (152) Stocklist (148) Sheet Offset (22) Converting (109)All Guillotine (12)Folding Machine (20)Perfect Binding (5)Saddle Stitching (4)Gathering (6)Miscellaneous (60)Stitching Machine (1)Cross Feeder (1)Web Offset (3) Paper Converting (4) Solid Board Converting (2) Corrugated Board Conv. (2) Preamplifiers (5) Accessory (5)

- Sell machine

- Service

- Contact

Blog - Stay informed

Wrapping unit

In the final stages of print production, protecting and presenting finished products is as crucial as the binding process itself. Wrapping units, often integrated into high-speed finishing lines, automate the packaging of books, magazines, or brochures, ensuring they reach customers in pristine condition while streamlining post-production workflows.

Date: 2025-04-30 • Author: Ahmet Karakus

WEKO AP 262

In high-speed sheetfed printing, preventing ink smudging and ensuring flawless sheet separation are critical to maintaining productivity. Powder application systems, such as the WEKO AP 262, address these challenges by delivering precise, controlled amounts of anti-set-off powder—a solution that keeps prints pristine even in demanding environments.

Date: 2025-04-26 • Author: Ahmet Karakus

Varidamp alcohol dampening system

In offset printing, achieving the perfect balance between ink and dampening solution is an art—one that directly impacts print clarity, color consistency, and production efficiency. Advanced alcohol dampening systems, like the Varidamp, refine this equilibrium, enabling printers to meet high demands for quality while adapting to diverse substrates and environmental conditions.

Date: 2025-04-22 • Author: Ahmet Karakus

Vacuum suction feeder

In high-volume printing and binding operations, the seamless handling of materials is critical. At the heart of this process lies a technology designed to ensure precision and reliability: vacuum suction feeding systems, which enable smooth, consistent sheet separation and transport without compromising speed or quality.

Date: 2025-04-18 • Author: Ahmet Karakus

UV dryer

In the fast-paced world of modern printing, efficiency and precision are non-negotiable. One innovation that has revolutionized the industry is UV curing technology—a process that accelerates drying times, enhances print quality, and unlocks creative possibilities.

Date: 2025-04-14 • Author: Ahmet Karakus

Ultrasonic double sheet detector

In the fast-paced world of industrial printing, precision and efficiency are paramount. One crucial feature that ensures smooth operation and high-quality output is the ultrasonic double sheet detector. This innovative technology plays a vital role in maintaining production flow and preventing common issues that can lead to downtime and material waste.

Date: 2025-04-10 • Author: Ahmet Karakus

Low-pile feeder

In the realm of material handling and finishing systems, the low-pile feeder stands out as a solution engineered for precision and uninterrupted workflow. By reimagining how substrates are fed into downstream processes, this feature addresses common bottlenecks in high-speed production environments.

Date: 2025-04-06 • Author: Ahmet Karakus

Low-pile delivery

In the fast-paced world of printing, efficiency and precision are non-negotiable. One innovation that quietly revolutionizes workflow is low-pile delivery—a feature designed to optimize output handling while maintaining quality and minimizing downtime.

Date: 2025-04-02 • Author: Ahmet Karakus

Laminating station

A laminating station is a crucial component in the printing and packaging industry, designed to enhance the durability, protection, and overall quality of printed materials. This process involves applying a thin layer of plastic film to the surface of the printed material, creating a protective barrier that enhances its longevity and appearance.

Date: 2025-03-29 • Author: Ahmet Karakus

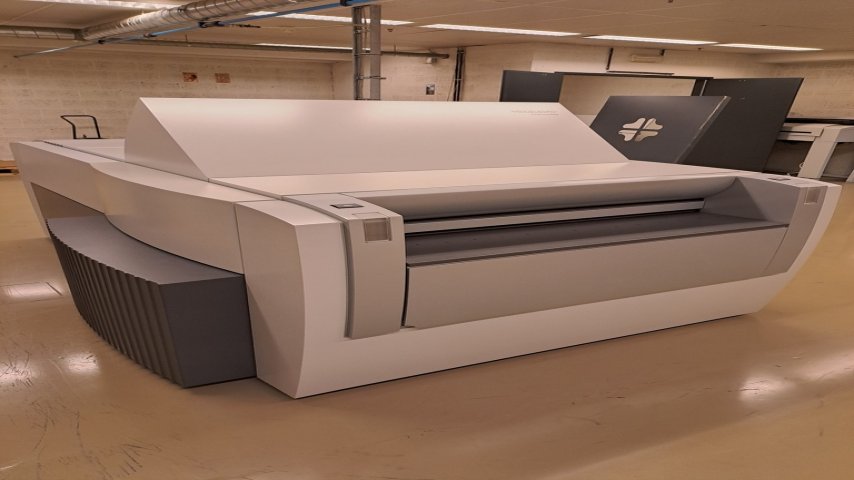

Cassette loader

A cassette loader is a crucial component in various printing systems, designed to streamline the process of loading and managing printing plates. This feature is particularly important in high-volume printing environments where efficiency and precision are paramount.

Date: 2025-03-25 • Author: Ahmet Karakus

Graphische Okkasionen Karakus

Our work consists of the international trade with graphic machines and equipments. Good contacts and over 25 years of experience assure our position on the international market.We distinguish ourselves through serious and uncomplicated handling. Our Monteure are guarantors for satisfied clients.

Imprint

Disclaimer

Blog

Manufacturer information

Contact

D-41849 Wassenberg

Tel: +49 - (0) 2432-98 595-0

Fax: +49 - (0) 2432-98 595-29

Email: info@gok-karakus.de