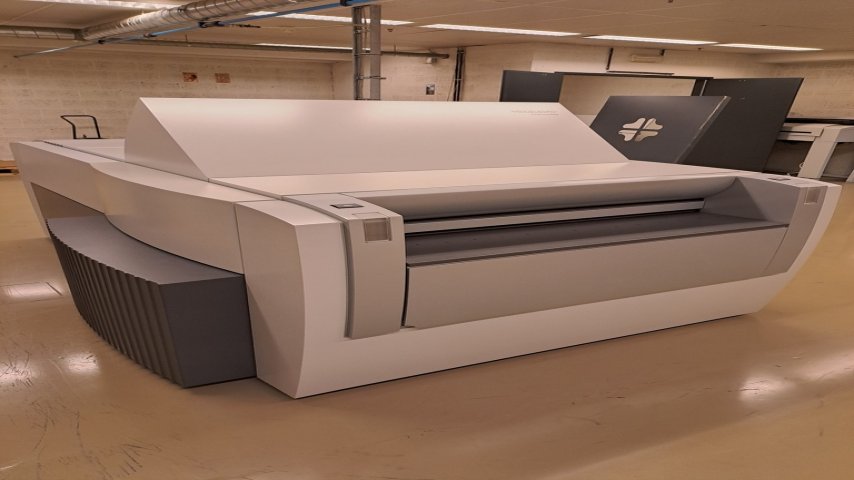

| Reference No. | 41288 |

| Year | 1973 |

| Manufacturer | Bobst |

| Type | SP 1120-E |

| Main Category | Solid Board Converting |

| Sub Category | Autoplaten |

| Size | 780x1120 mm |

| Price | 29 000 € |

Status : Idle

Location : Germany

Incoterm: FCA

Description:

- Die Cutting Machine with Stripping Unit

- Running speed: Max. 6000 Sheets/Hour

- Cutting force up to: 300 Tons

- Platform

- Pallet Feeder with Non-Stop device

- Pull guide (OS) with Double Sheet Detector

- Centerline

- Refurbished 1980

- Feeder with pre-pile device

- Continuous feed and delivery

- 2 cutting chase

- Solid board: 0.060" (1.5 mm)

- Paper: from 0.005" (90 grams/sq. meter)

- Max. sheet 44" x 31 1/2" (1120 mm x 800 mm)

- Min. sheet 17 3/4" x 15" (450 mm x 380 mm)

- Corrugated 0.160" (4 mm)

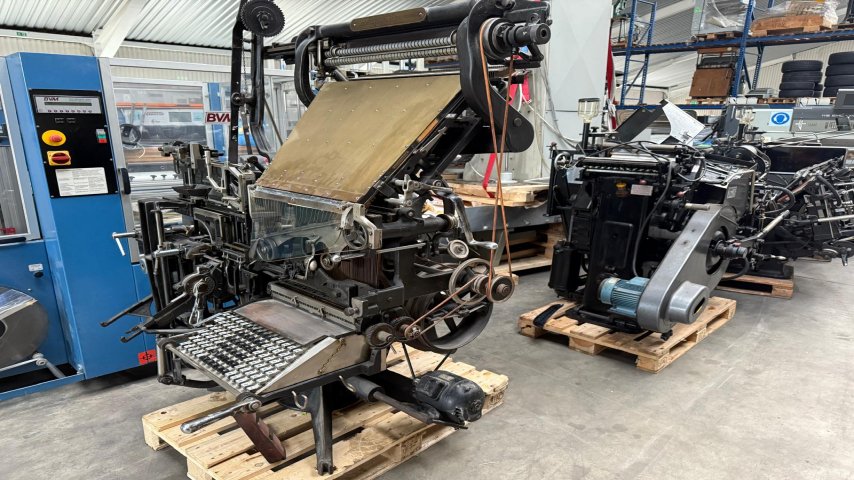

The Bobst SP 1120-E is a punching machine equipped with a stripping unit, designed for efficient and precise punching operations. Manufactured by Bobst in 1973, this model is located in Germany, with pricing available upon request. It features a format of 780 x 1120 mm and can handle sheet sizes ranging from a maximum of 800 x 1120 mm to a minimum of 380 x 450 cm. The machine boasts a running speed of up to 6,000 sheets per hour and a cutting force of up to 300 tons. Additional features include a platform, pallet feeding with a non-stop device, sheet feeding (OS) with double sheet detection, and a centerline.