- Home

-

Machinery List

Machinery List (152) Stocklist (148) Sheet Offset (22) Converting (109)All Guillotine (12)Folding Machine (20)Perfect Binding (5)Saddle Stitching (4)Gathering (6)Miscellaneous (60)Stitching Machine (1)Cross Feeder (1)Web Offset (3) Paper Converting (4) Solid Board Converting (2) Corrugated Board Conv. (2) Preamplifiers (5) Accessory (5)

- Sell machine

- Service

- Contact

Blog - Stay informed

Perfecting 2/2 - 4/0 / 1/1-2/0

In the world of printing, especially in the commercial offset printing industry, perfecting refers to the process of printing on both sides of a sheet in a single pass through the press. This technique not only enhances productivity by eliminating the need for paper re-feeding but also allows for a wide range of print finishes and configurations to meet the diverse needs of customers. One of the key factors in perfecting is understanding the different formats, which dictate how ink is applied to the front and back sides of a sheet.

Date: 2024-02-08 • Author: Ahmet Karakus

WEKO powder spray / Weko AP 110

In the world of printing, particularly in offset printing, ensuring the quality of each printed sheet is not just about the print itself, but also about how it is handled after coming off the press. A critical aspect of this is the prevention of ink set-off and smudging, which can significantly affect the quality of printed materials. One of the most effective solutions for this problem is the application of powder spray, a technique used to help manage the delicate balance between freshly printed ink and smooth handling during the finishing process.

Date: 2024-01-09 • Author: Ahmet Karakus

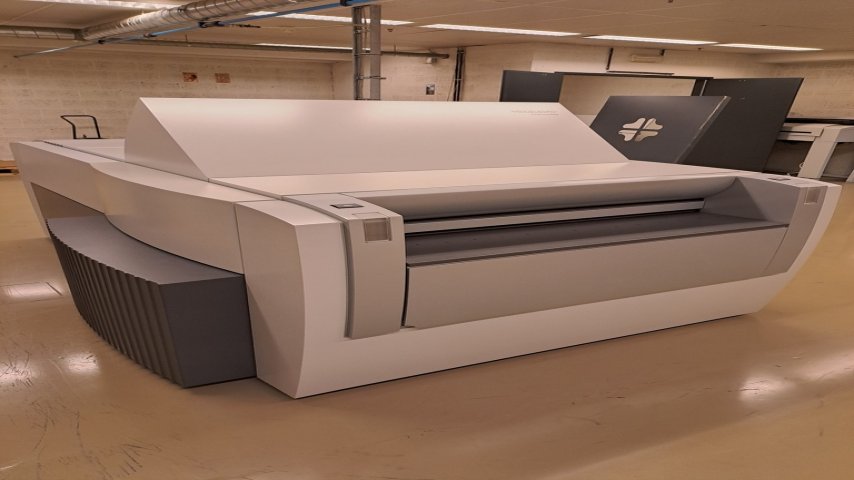

Web inspection type: Powerscope 4000

In the world of high-speed printing, particularly in label and packaging production, the importance of ensuring flawless quality control cannot be overstated. One of the most advanced solutions in maintaining this level of quality is a web inspection system. These systems are designed to monitor and detect any imperfections on the printed material as it moves through the production process, ensuring that each print job meets the highest standards before it reaches the end of the line.

Date: 2023-12-10 • Author: Ahmet Karakus

Washing device: Automatic blanket & roller wash up

In the fast-paced world of commercial printing, maintaining the cleanliness of printing presses is crucial to achieving high-quality results and ensuring smooth production. One of the most important tasks in this regard is the cleaning of blankets and rollers, which come into direct contact with ink during printing. Over time, ink residues, dust, and other contaminants can build up on these surfaces, leading to print defects, color inconsistencies, and downtime for maintenance. This is where an automatic blanket and roller wash-up device becomes an invaluable asset to any printing operation.

Date: 2023-11-10 • Author: Ahmet Karakus

Pre-melter for hot-melt spine gluing

In the world of bookbinding and finishing, the quality and durability of the spine glue are critical to ensuring that books can withstand daily handling while retaining their integrity. One of the most essential tools in this process is the premelter for hotmelt spine gluing. This device is responsible for ensuring that the adhesive used in spine binding is applied consistently and effectively, contributing to a high-quality finished product.

Date: 2023-10-11 • Author: Ahmet Karakus

Vacuum transport unit at the delivery after the 5-colors

In the world of modern printing, efficiency and precision are paramount, particularly when it comes to handling the delicate process of transporting printed materials. The vacuum transport unit, particularly at the delivery stage after a multi-color print process, plays a crucial role in ensuring that the final product is delivered in perfect condition, ready for the next steps in the production chain.

Date: 2023-09-11 • Author: Ahmet Karakus

UV washer from FLEXOWASH

In the fast-evolving world of printing, particularly in the label and packaging industry, maintaining cleanliness and efficiency is essential to ensuring top-quality output and smooth production processes. One of the critical tools in achieving this is the UV washer, such as the one offered by FLEXOWASH. This innovative cleaning system plays a vital role in preserving print quality and ensuring that machines continue to operate at their full potential throughout high-volume production runs.

Date: 2023-08-12 • Author: Ahmet Karakus

UV drying system: 6 GEW UV dryers

In the fast-paced world of print production, drying systems play an essential role in ensuring that prints are fully cured and ready for the next stage of the process. UV drying systems, in particular, have become increasingly popular due to their efficiency and ability to handle a wide range of printing materials. The use of a high-quality UV drying system, such as one featuring multiple GEW UV dryers, offers numerous advantages in terms of speed, energy efficiency, and print quality.

Date: 2023-07-13 • Author: Ahmet Karakus

Trio-Cut device

In the print finishing industry, precision and efficiency are paramount when it comes to cutting, folding, and binding printed materials. A critical aspect of this process is the cutting stage, where products are trimmed to exact specifications. The Trio-Cut device stands out as an essential tool in achieving high-quality results with speed and accuracy in the cutting process.

Date: 2023-06-13 • Author: Ahmet Karakus

TRESU Coating Supply & Cleaning Device

In the high-speed world of print production, maintaining the quality of printed materials while keeping the workflow smooth and efficient is critical. One key area where precision and cleanliness are paramount is in the application and maintenance of coatings. This is where the TRESU Coating Supply & Cleaning Device comes into play, offering an innovative solution for managing coating applications and ensuring minimal downtime during production.

Date: 2023-05-14 • Author: Ahmet Karakus

Graphische Okkasionen Karakus

Our work consists of the international trade with graphic machines and equipments. Good contacts and over 25 years of experience assure our position on the international market.We distinguish ourselves through serious and uncomplicated handling. Our Monteure are guarantors for satisfied clients.

Imprint

Disclaimer

Blog

Manufacturer information

Contact

D-41849 Wassenberg

Tel: +49 - (0) 2432-98 595-0

Fax: +49 - (0) 2432-98 595-29

Email: info@gok-karakus.de