- Home

-

Machinery List

Machinery List (152) Stocklist (148) Sheet Offset (22) Converting (109)All Guillotine (12)Folding Machine (20)Perfect Binding (5)Saddle Stitching (4)Gathering (6)Miscellaneous (60)Stitching Machine (1)Cross Feeder (1)Web Offset (3) Paper Converting (4) Solid Board Converting (2) Corrugated Board Conv. (2) Preamplifiers (5) Accessory (5)

- Sell machine

- Service

- Contact

Blog - Stay informed

Weko powder spray

Weko powder sprays are an essential component in the printing industry, playing a crucial role in enhancing the efficiency and quality of printing processes. These innovative devices are designed to apply a fine layer of powder to printed surfaces, which serves multiple purposes.

Date: 2024-12-04 • Author: Ahmet Karakus

Two-head paper drilling machine

In the world of printing and finishing, precision and efficiency are paramount. One critical operation that requires both is paper drilling, particularly for tasks like binding, booklet creation, and ensuring that paper stacks are properly aligned for subsequent processing. A two-head paper drilling machine has emerged as a key solution for companies aiming to streamline their production processes and meet high-volume demands while maintaining accuracy.

Date: 2024-11-04 • Author: Ahmet Karakus

Two-lane operation

In the world of packaging and finishing, efficiency is the key to keeping production costs down while maintaining high quality. One of the strategies to achieve this efficiency, especially in operations that involve packaging with windows, is the use of two-lane operation. This concept has become a hallmark of modern packaging machinery and has proven to be a game-changer for many businesses.

Date: 2024-10-05 • Author: Ahmet Karakus

Two types of ink Eco Ultra and Universal Mild Solvent (UMS)

In the world of digital printing, the quality and longevity of prints are heavily dependent on the type of ink used. Whether you’re producing banners, signage, textiles, or other printed materials, selecting the right ink is crucial for achieving vibrant colors, durability, and precision. Among the various ink options available, two types that stand out for their versatility and quality are Eco Ultra Ink and Universal Mild Solvent (UMS) Ink. These two ink types are popular choices in the printing industry, offering different benefits tailored to specific printing needs. Let’s take a closer look at each type and explore their respective advantages.

Date: 2024-09-05 • Author: Ahmet Karakus

Feeder: Edge Feeder (MIRUS)

In the world of industrial printing and finishing, efficiency and precision are paramount. Whether you're working with paper, cardboard, or specialized materials, ensuring that each sheet is fed correctly through the machine can significantly impact the overall quality and efficiency of the production process. One advanced solution that has revolutionized feeding mechanisms in printing and finishing is the Edge Feeder, and specifically, the MIRUS Edge Feeder system.

Date: 2024-08-06 • Author: Ahmet Karakus

Feeding system Vacuum belt

In the world of modern printing and finishing, precision is key. Every stage of the process—from feeding and printing to cutting and binding—requires high levels of accuracy to ensure the final product meets the highest quality standards. One critical aspect of this precision lies in the feeding system used to transport materials through the machine. Among the various technologies employed for this purpose, the vacuum belt feeding system has emerged as a game-changer in terms of both efficiency and accuracy.

Date: 2024-07-07 • Author: Ahmet Karakus

Circumferential, assial and diagonal registers

In the world of high-precision printing, achieving accurate and consistent print alignment is crucial for producing high-quality results. Whether it’s for packaging, labels, or commercial print jobs, even the slightest misalignment can lead to defects, wasted materials, and increased production time. To ensure flawless printing, advanced printing technologies incorporate various registration systems designed to align the printed images correctly on the substrate. Among these, circumferential, axial, and diagonal registers are key concepts that help optimize alignment and reduce errors during the printing process.

Date: 2024-06-07 • Author: Ahmet Karakus

Pull mark control

In the world of high-quality printing, precision and consistency are paramount. Every step of the printing process, from pre-press to finishing, requires careful monitoring and adjustment to ensure the final product meets the highest standards. One critical area where this precision is especially important is in controlling the pull marks during the printing process.

Date: 2024-05-08 • Author: Ahmet Karakus

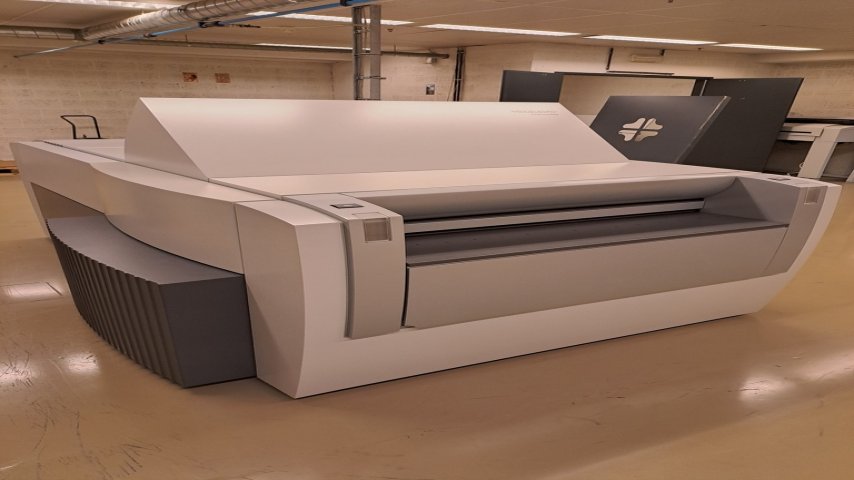

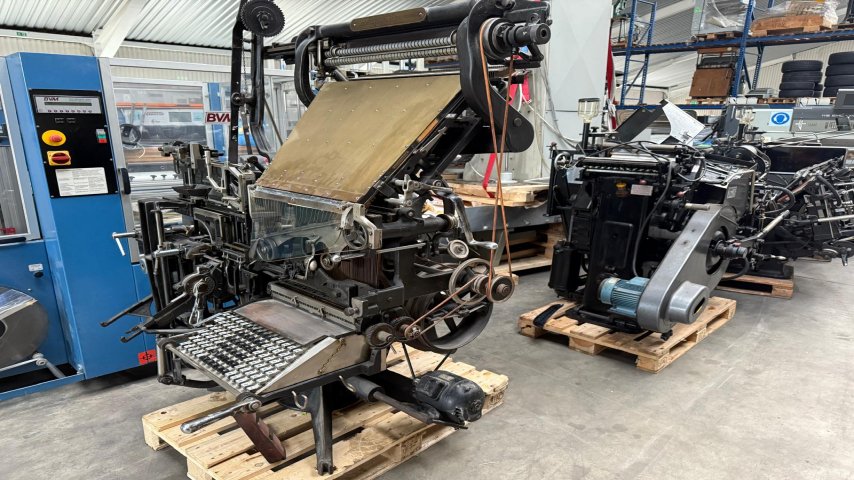

As seen

In the printing industry, the term “as seen” often comes into play when discussing used equipment, machinery, and tools that are available for purchase. While the allure of new, state-of-the-art machines is undeniable, the growing interest in “as seen” equipment has become a compelling option for businesses looking to maximize their investment and expand their capabilities without breaking the bank.

Date: 2024-04-08 • Author: Ahmet Karakus

Tool temperature controller

In the fast-paced world of high-quality printing and finishing, precision is the key to success. Whether it’s in packaging, labels, or commercial printing, the final product must meet the highest standards. This is where a tool temperature controller becomes indispensable, particularly in processes that involve laminating and coating. While it might seem like a small component in the overall production line, the tool temperature controller plays a significant role in ensuring consistent, high-quality output.

Date: 2024-03-09 • Author: Ahmet Karakus

Graphische Okkasionen Karakus

Our work consists of the international trade with graphic machines and equipments. Good contacts and over 25 years of experience assure our position on the international market.We distinguish ourselves through serious and uncomplicated handling. Our Monteure are guarantors for satisfied clients.

Imprint

Disclaimer

Blog

Manufacturer information

Contact

D-41849 Wassenberg

Tel: +49 - (0) 2432-98 595-0

Fax: +49 - (0) 2432-98 595-29

Email: info@gok-karakus.de