- Home

-

Machinery List

Machinery List (152) Stocklist (148) Sheet Offset (22) Converting (109)All Guillotine (12)Folding Machine (20)Perfect Binding (5)Saddle Stitching (4)Gathering (6)Miscellaneous (60)Stitching Machine (1)Cross Feeder (1)Web Offset (3) Paper Converting (4) Solid Board Converting (2) Corrugated Board Conv. (2) Preamplifiers (5) Accessory (5)

- Sell machine

- Service

- Contact

Blog - Stay informed

Side tables with air

In high-precision cutting environments, every element of the workflow matters—down to how materials are handled before they even reach the blade. That’s where side tables with air come into play, serving as more than just auxiliary surfaces. They are an essential part of modern cutting systems, designed to improve efficiency, ergonomics, and material integrity.

Date: 2022-06-18 • Author: Ahmet Karakus

Streamfeeder

In the realm of professional printing, efficiency and precision are paramount. As demand increases for high-volume, high-quality output, even the smallest enhancements in workflow can result in significant gains. One often-overlooked component that plays a crucial role in this process is the streamfeeder.

Date: 2022-05-19 • Author: Ahmet Karakus

Quick change slitter shafts

In the high-demand world of print finishing, efficiency and speed are crucial for maintaining profitability and meeting customer deadlines. A significant factor that can make or break the productivity of any print finishing process is the ability to make quick adjustments and changes during production. This is where quick change slitter shafts come into play. These components provide a solution to one of the most time-consuming aspects of the finishing process—changing and adjusting the slitter blades—and help ensure the overall efficiency of the production line.

Date: 2022-04-19 • Author: Ahmet Karakus

Quick action plate clamps

In the fast-paced world of commercial printing, speed, efficiency, and precision are crucial. One of the key factors that contributes to achieving these goals is the use of quick action plate clamps. These components are an essential part of any modern printing press, providing an innovative solution to streamline plate changing processes while ensuring the highest standards of print quality.

Date: 2022-03-20 • Author: Ahmet Karakus

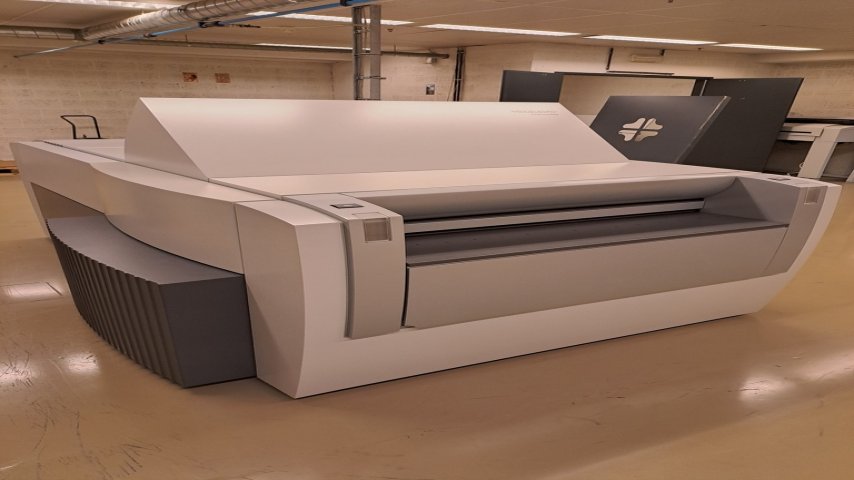

SAPC semi-automatic plate changer

In the world of modern printing, efficiency, accuracy, and minimizing downtime are key factors that drive success in any printing press operation. One of the most crucial elements to ensure these goals is the semi-automatic plate changer (SAPC). By automating the plate-changing process, this system provides numerous benefits that streamline operations, reduce labor costs, and improve overall production efficiency.

Date: 2022-02-18 • Author: Ahmet Karakus

RyobiMatic dampening system with Technotrans

In the world of offset printing, one of the critical factors that can influence the quality of the print job is the dampening system. The dampening system is responsible for applying a thin layer of fountain solution to the printing plate, which works in tandem with the ink to ensure proper ink adhesion on the image areas while keeping non-image areas free from ink. An advanced dampening system can have a significant impact on both the consistency and efficiency of the printing process, and systems like the RyobiMatic dampening system with Technotrans have set a high standard in the industry.

Date: 2022-01-19 • Author: Ahmet Karakus

Rotometrics pressure control at the die-cutting station

In the world of precision die-cutting, achieving consistent and accurate results is paramount. One of the key elements in ensuring high-quality die-cutting processes is effective pressure control at the die-cutting station. This system is crucial in managing the interaction between the die, the substrate, and the cutting process, ensuring that each cut is sharp, precise, and meets the required specifications.

Date: 2021-12-20 • Author: Ahmet Karakus

ROLAND dampening system

In modern printing operations, achieving precise and consistent ink transfer is critical for producing high-quality prints. One of the essential components that ensures this precision is the dampening system. While it may not always take center stage, the dampening system plays a crucial role in offset printing, influencing both the quality and efficiency of the print job.

Date: 2021-11-20 • Author: Ahmet Karakus

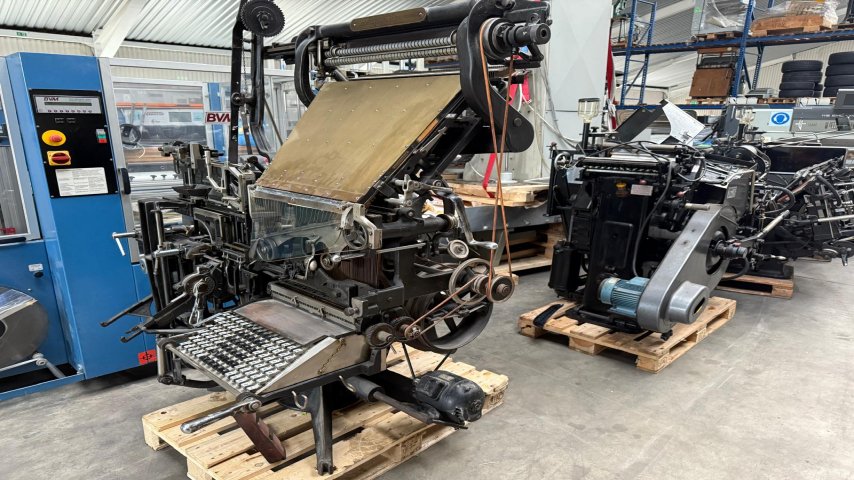

Roland sheet feeder

In the fast-paced world of commercial printing, efficiency, precision, and smooth operation are the cornerstones of success. One key element that significantly impacts the overall efficiency of the printing process is the sheet feeder. The role of a sheet feeder is essential in ensuring that paper is fed into the printing press smoothly and consistently, without interruptions or delays. Among the various feeder systems available, the Roland sheet feeder stands out for its ability to enhance productivity and reduce downtime, making it a critical part of high-performance printing operations.

Date: 2021-10-21 • Author: Ahmet Karakus

Fine register adjustment +20 / -20

In the world of screen printing, achieving precise and consistent registration is paramount to producing high-quality prints. One of the crucial components that help operators maintain this accuracy is the fine register adjustment system. This system allows for minute adjustments to be made to the registration of the print, ensuring that the design is perfectly aligned on every sheet, every time. The ability to make fine-tuned adjustments is particularly valuable in multi-color printing, where even a small misalignment can lead to blurred or poorly positioned images.

Date: 2021-09-21 • Author: Ahmet Karakus

Graphische Okkasionen Karakus

Our work consists of the international trade with graphic machines and equipments. Good contacts and over 25 years of experience assure our position on the international market.We distinguish ourselves through serious and uncomplicated handling. Our Monteure are guarantors for satisfied clients.

Imprint

Disclaimer

Blog

Manufacturer information

Contact

D-41849 Wassenberg

Tel: +49 - (0) 2432-98 595-0

Fax: +49 - (0) 2432-98 595-29

Email: info@gok-karakus.de