- Home

-

Machinery List

Machinery List (152) Stocklist (148) Sheet Offset (22) Converting (109)All Guillotine (12)Folding Machine (20)Perfect Binding (5)Saddle Stitching (4)Gathering (6)Miscellaneous (60)Stitching Machine (1)Cross Feeder (1)Web Offset (3) Paper Converting (4) Solid Board Converting (2) Corrugated Board Conv. (2) Preamplifiers (5) Accessory (5)

- Sell machine

- Service

- Contact

Blog - Stay informed

Grafix Exactomat powder spray

In the printing industry, achieving optimal print quality and smooth production workflows is essential, especially when dealing with high-speed printing jobs. One of the key components that ensures a seamless production process, particularly for offset printing, is the use of powder spray systems. These systems, such as Grafix Exactomat powder spray units, play a crucial role in preventing ink smudging, maintaining print quality, and improving overall operational efficiency.

Date: 2018-05-10 • Author: Ahmet Karakus

Grafix Digitronic powder device

In the print industry, maintaining a high level of print quality while ensuring the production process runs efficiently is essential. One of the lesser-discussed but crucial components of achieving consistent, high-quality results is the use of powder devices in post-press finishing. These devices, especially digitally controlled powder applicators, play a vital role in ensuring that printed materials meet the demands of both print quality and operational efficiency.

Date: 2018-04-10 • Author: Ahmet Karakus

Grafix Alphatronic 200

In the world of modern printing, achieving superior print quality while maintaining high productivity is a constant challenge. As print jobs grow in complexity and demand, it becomes essential for printers to have access to advanced technology that can enhance the final output without compromising on speed or efficiency. One such solution that plays a critical role in this regard is automatic control systems designed to optimize various stages of the printing process.

Date: 2018-03-11 • Author: Ahmet Karakus

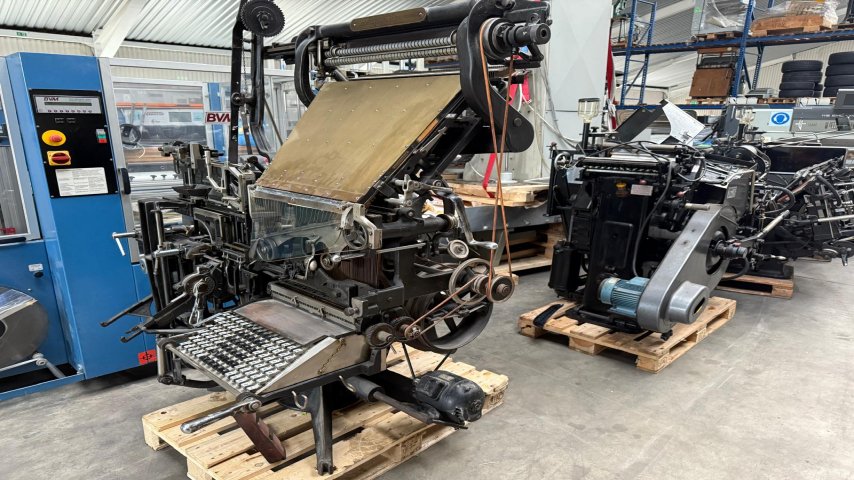

Straight machine

In the print industry, the term straight machine refers to printing presses that are designed to handle single-sided printing jobs without the complexity of additional in-line processes such as coating or varnishing. These presses are built for efficiency and precision, making them a popular choice in commercial printing, packaging, and various other sectors that require high-quality, fast printing on one side of the paper.

Date: 2018-02-09 • Author: Ahmet Karakus

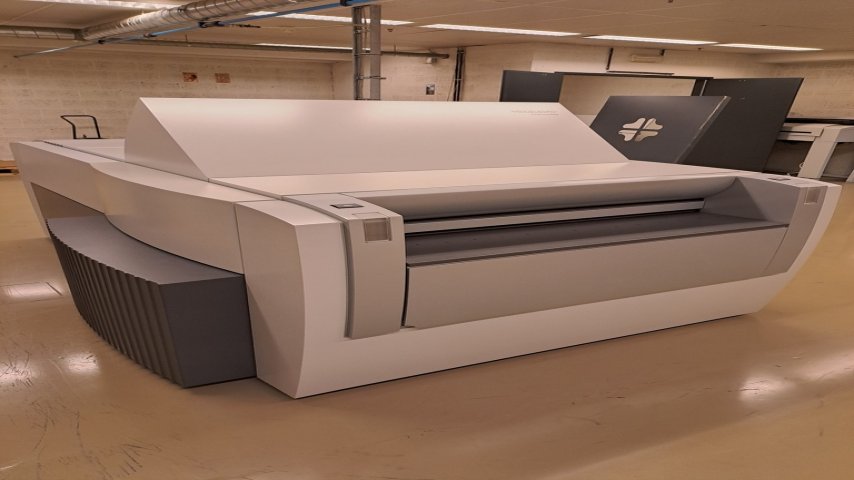

FTR 2000 trimmer front cutter

In the world of print finishing, precision and efficiency are paramount to ensuring high-quality outputs. One critical piece of equipment that plays a crucial role in achieving these standards is the front trimmer cutter. This essential tool helps optimize the finishing process by precisely trimming the leading edges of printed materials, such as booklets, brochures, and magazines, as they move through the post-press stages.

Date: 2018-01-10 • Author: Ahmet Karakus

Photocells

In the world of modern printing, precision and efficiency are paramount. One technology that plays a crucial role in achieving both is the photocell. These devices, also known as photoelectric sensors, are used extensively in printing presses and other machinery to monitor, detect, and control various elements of the production process. By converting light into an electrical signal, photocells provide real-time data that helps automate processes, enhance accuracy, and improve overall workflow.

Date: 2017-12-11 • Author: Ahmet Karakus

Conveyor belts

In the world of modern manufacturing and production, conveyor belts play an integral role in the efficient and seamless movement of materials. Whether in the printing industry, packaging, or assembly lines, conveyor belts provide a reliable and automated solution to ensure products move through various stages of production with minimal human intervention. In the context of print finishing and binding, conveyor belts are particularly valuable for transporting printed sheets, signatures, or finished products throughout the production process.

Date: 2017-11-11 • Author: Ahmet Karakus

Flat pile feeder

In the world of print production, efficiency and precision are key to maintaining high-quality outputs. One critical component that plays a vital role in streamlining the printing process is the flat pile feeder. Widely used in commercial printing, this technology ensures smooth, reliable feeding of sheets into printing machines. By optimizing the handling of paper, the flat pile feeder helps maintain consistent print quality while minimizing downtime and waste.

Date: 2017-10-12 • Author: Ahmet Karakus

Conventional dampening system / Conventional dampening system

In the world of offset printing, the dampening system plays a crucial role in achieving high-quality prints. The conventional dampening system, a staple in many printing presses, is a tried-and-true method for delivering precise control over ink distribution on printing plates. It ensures that ink adheres to the non-image areas while repelling it from the image areas, which is essential for producing sharp, clean prints. While newer technologies have emerged, the conventional dampening system remains an essential tool in print shops due to its reliability and simplicity.

Date: 2017-09-12 • Author: Ahmet Karakus

Folding and creasing

In the world of print finishing, two key processes that are crucial for transforming printed sheets into professional, high-quality final products are folding and creasing. These processes are essential when it comes to creating brochures, catalogs, flyers, and other printed materials that need to be folded neatly and cleanly. While these might seem like simple steps, they require specialized equipment and precise techniques to ensure perfect results. Understanding the roles of both folding and creasing—and how they complement each other—can make a significant difference in the final outcome of printed products.

Date: 2017-08-13 • Author: Ahmet Karakus

Graphische Okkasionen Karakus

Our work consists of the international trade with graphic machines and equipments. Good contacts and over 25 years of experience assure our position on the international market.We distinguish ourselves through serious and uncomplicated handling. Our Monteure are guarantors for satisfied clients.

Imprint

Disclaimer

Blog

Manufacturer information

Contact

D-41849 Wassenberg

Tel: +49 - (0) 2432-98 595-0

Fax: +49 - (0) 2432-98 595-29

Email: info@gok-karakus.de